HOME > Research > Phase Change RAM

HOME > Research > Phase Change RAM

Phase Change RAM

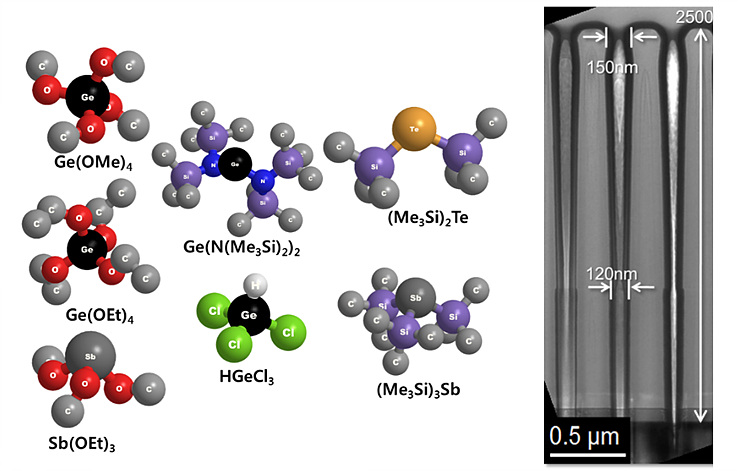

Ge-Sb-Te ALD process

The current PCRAM technology generally adopts a planar

structured (so called T-shaped) cell. However, further scaling is difficult

with a T-shaped cell due to the extremely low heating efficiency (only ~ 2 %)

of this structure. Plugging the PC material into a small contact hole (called

the confined cell structure) was suggested as the most efficient method to

improve the cell efficiency and increase the integration density. However, the

confined cell structure requires the PC material to be deposited with highly

conformal, reproducible, and rapid growth properties, which can usually be

accomplished by chemical vapor deposition (CVD) and atomic layer deposition

(ALD). However, the ALD of a PC material (most typically the Ge-Sb-Te

ternary material) is difficult because of the strong bond energy between the

metal ions (Ge, Sb and Te) and C as well as their covalent nature in most

common alkyl-based metal-organic precursors.

A genuine thermal ALD of Ge-Sb-Te phase changing material

layers at low temperatures (~ 70 oC), of which the composition lies

on the GeTe2 – Sb2Te3 tie line, is

realized using silyl-Te and alkoxy-Ge and alkoxy-Sb without the use of any

reaction gas. The strong affinity between the silyl group in the Te-precursor

and oxygen ions in the Ge- and Sb-precursors provide a fluent thermal ALD

reaction route to the system. This chemistry-specific ALD process was quite

robust against process variations resulting in highly conformal, smooth, and

reproducible film growth over a contact hole structure with an extreme

geometry.

Although the research group developed ALD of Ge-Sb-Te ternary

material, there were limitations in composition which lies on GeTe2-Sb2Te3

tie line. For various composition, novel Ge(II) precursors/silyl-Sb precursor

was suggested. As a result, stoichiometric GeTe and Sb-rich SbxTey

ALD were also developed. Thus, large area in Ge-Sb-Te ternary phase diagram can

be covered by combining these ALD processes with previously developed

processes.

Related Paper:

T Eom, et al., Chemistry of Materials, 11, 24,

2099 (2012)

T Eom, et al., Chemistry of Materials, 4, 26,

1583 (2014)

T Eom, et al., Chemistry of Materials, 10, 27,

3707 (2015)

T Eom, et al., Journal of Materials Chemistry C, 3, 1365

(2015)

PCRAM Cell Fabrication

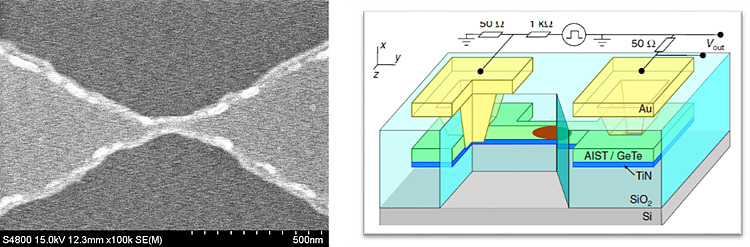

In order to evaluate/improve the electrical properties of

chalcogenide materials for PCRAM application, we design and fabricate various

cell geometries with e-beam lithography. The advantages of e-beam lithography

include high resolution of ~20nm and versatile pattern formations. We also

investigate different doping materials which can be applied to ALD and enhance

PCRAM device performances.

Ovonic Threshold Switch for Memory Selecotr Device

D. Adler, et al., Rev. Mod. Phys., 1978. D. C. Kau, et al., IEDM 2009

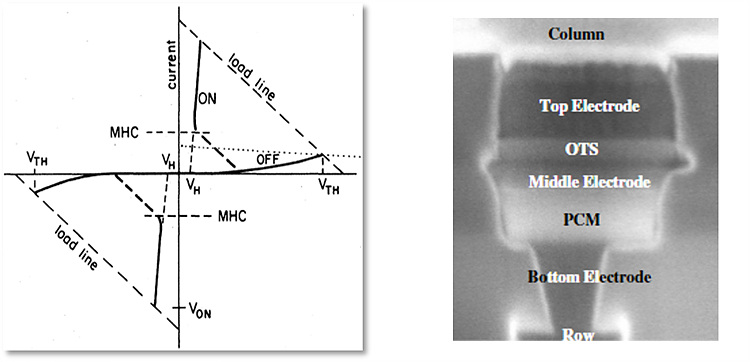

3D vertical cross-point array is a promising approach for

enabling next generation ultra-high density nonvolatile memory. However, the

implementation of resistive memory (e.g., RRAM and PCRAM) into dense

cross-point memory array must be addressed by a selector device with a strong

nonlinear IV characteristic in order to suppress sneak current paths.

Here, we focus on developing an ovonic threshold switch (OTS)

which is based on chalcogenide materials for memory selector application. Since

3D vertical architecture requires a deposition method with exceptional

conformity on high aspect ratio, we are interested in using atomic layer

deposition to achieve this goal.

Resistive Switching Behavior or Chalcogenide without Phase Change

Among the chalcogenide materials, alloys and compounds of Ge,

Sb and Te are one of the major materials for phase change memory (PCRAM.) The

applications such as a non-volatile memory entirely depend on the electrical

resistivity difference between crystalline and amorphous phase. This phase

change effect and consequent resistivity change by polarity-independent

electric pulse require high current density, which leads to high power

consumption issue that has been an obstacle for commercialization of PCRAM.

Chalcogenides play an important role as the electrolytes in

the electrochemical metallization (ECM) cell. Because the operation of the ECM

cell does not depend on the (local) melting and subsequent amorphization of the

chalcogenides, it does not require an excessively high reset switching from a

low-resistance state (LRS) to a high-resistance state (HRS) current, which was

the most significant problem in PCRAM. Nevertheless, the adoption of Ag or Cu

as the active metallic element could pose a problem such as contamination

issue. According to this concern, recent studies reported on the

chalcogenide-based ReRAM cell, wherein the conducting filament is comprised of

non-Cu element inside the chalcogenide alloys as a solid electrolyte.

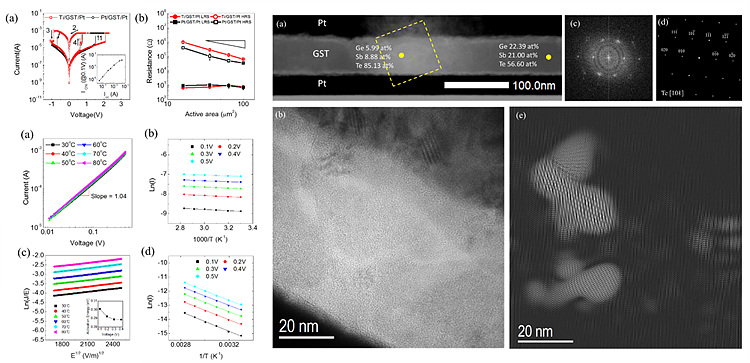

Our research group focuses on polarity-dependent resistive

switching in amorphous Ge2Sb2Te5 (GST) thin

film by formation and rupture of Te-rich conducting filament, which does not

involve any phase change and thus can overcome demerits of conventional PCRAM.

Related paper:

Sijung Yoo et al., Nanoscale, 7, 6340-6347 (2015)