HOME > Research > Dynamic RAM

HOME > Research > Dynamic RAM

Dynamic RAM

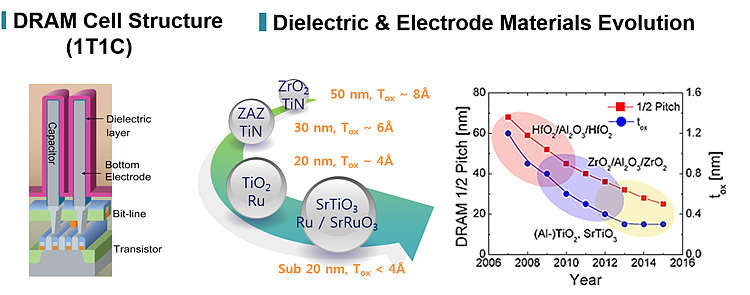

Recently, for sub 20nm scaled DRAM, capacitor structure has been changed to a metal-insulator-metal (MIM) structure in order to remove interfacial layers with low dielectric constant at the interface between polysilicon and dielectric material in SIS or MIS capacitors.

Due to the extremely small size of the capacitor, a three-dimensional structures such as trench hole/stack type are required for Gbit-scale DRAMs to obtain sufficient storage capacitance even though dielectrics with a high permittivity are used. Therefore, a ALD/CVD technique providing excellent conformality is required in order to fabricate the top and bottom electrodes as well as the dielectric films.

Ru and RuO2 are promising materials due to their good susceptibility to dry etching, low resistivity (Ru~7 μΩ-cm, RuO2~30 μΩ-cm), high chemical stability and high work function (Ru~4.7 eV, RuO2~5.1 eV) compared to the currently-used TiN electrode (~4.2 eV).

The use of rare earth ruthenium oxide materials, such as SrRuO3 (SRO), as electrodes or as interlayer between the electrode and high-k for ferroelectric and DRAM applications is mentioned in various roadmaps due to the good lattice matching with SrTiO3(STO) and relatively higher polarization property than elemental electrode.

Electrode materials for DRAM capacitors

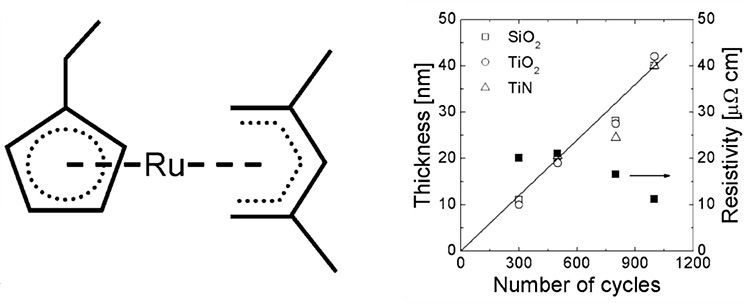

Deposition of ALD-Ru Electrode with DER precursor

There are lots precursor for deposition of Ru film by ALD

method, such as Ru(EtCp)2, Ru(thd)2, etc. Among them, we have studied the

deposition method of Ru electrode with DER precursor

(2,4-(Dimethylpentadienyl)(ethylcyclopentadienyl)Ru) by ALD method using liquid

injection system(LDI). Unlike other conventional ALD system, such as

bubbler-type, LDI uses heated vaporizer. The precursor is injected to vaporizer

in liquid state and vaporized, then carrier gas deliver the vaporized precursor

into reaction chamber.

Pure and conformal Ru electrode films are deposited.

S. K. Kim et al, J.Electrochem.Soc., 154(2), 2007

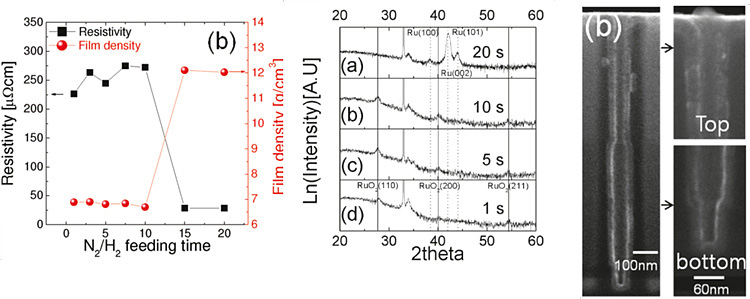

Pulsed CVD growth of Ru/RuO2 with RuO4 precursor

RuO4 precursor has very simple structure with

small molecular size, which makes it adoptable for deposition of Ru or RuO2

electrode films on complex-structured substrate. Over the temperature of 190ºC,

the RuO4 precursor is thermally decomposed to RuO2 phase

and self-limited growth behavior of ALD method is not shown. However, high

volatility of RuO4 molecule makes it possible that precursor

diffuses in short time and conformal film is deposited.

Phases of electrode films, Ru or RuO2, could be

controlled by injection time of H2-reduction gas, RuO2

for shorter H2 injection time and Ru for longer time. RuO2

films deposited by thermal decomposition of RuO4 precursor are

reduced to intermediate states, which are different with H2

injection time.

Related Paper:

J. H. Han, et al., Chem.Mater, 21.2, 2009

J. H. Han, et al., Chem.Mater, 22, 2010

J. H. Han, et al., Chem.Mater,

24.8, 2012

ALD growth of Ru electrode with RuO4 precursor

RuO4 precursor has been used for pulsed CVD growth

of Ru or RuO2 electrodes but ALD growth behavior is also shown at

low temperature. Under the decomposition temperature of RuO4

precursor, self-limited growth behavior which is a characteristic of ALD

deposition is observed. Deposited Ru electrode has low resistivity (~20μΩ-cm)

and low impurities.

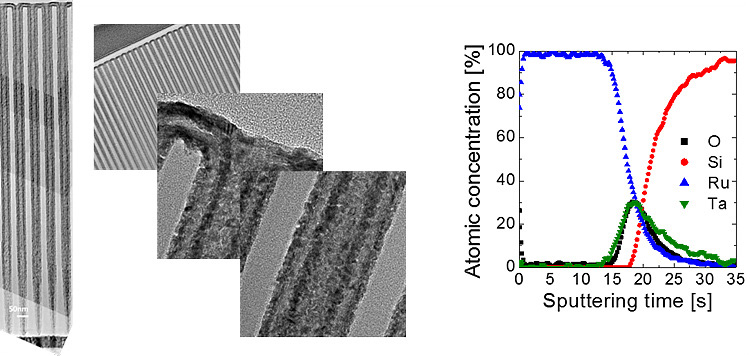

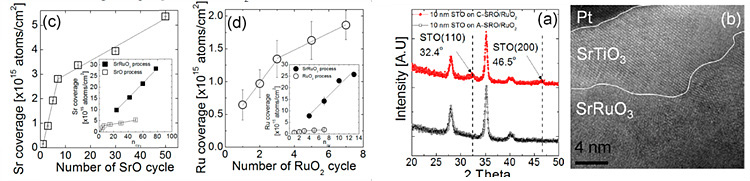

ALD/CVD combined growth of SrRuO3

electrode

Strontium Ruthenate (SrRuO3, SRO) which has

perovskite structure and high work function value is being studied for

electrode materials for SrTiO3 dielectric film since it has good

lattice matching with STO film.

Deposition sequence of SRO electrode consists of few

subcycles that alternating ALD-SrO cycles and CVD-RuO2 cycles.

Generally, deposition of ternary system (oxide with two cations) is really

complicated since non-ideal ALD reactions could be shown between each layer. In

case of SRO, ALD-SrO layer shown initial excessive growth behavior due to

existence of RuO2 layer, which is not observed from the ALD method

of only SrO layer. Controlling excessive growth is very important since it

could degrade step coverage of electrode film. Improving the conformallity of

SRO film is being studied in several ways.

Related Paper:

J. H. Han, et al., Chem.Mater, 24, 2012

Dielectric materials for DRAM capacitors

The technology road map for memory devices states that tox(EOT, equivalent oxide thickness) less than 0.5nm is necessary for the DRAMs with a design rule of 20nm. It is also noted that there are no known material solutions to serve this purpose. Reducing the thickness of the dielectric films with k values ~20-30 to achieve the required tox results in unacceptably high leakage currents.

Among the various dielectric films, TiO2 thin

film in rutile phase exhibits a k value ~100 and therefore can be used for

DRAMs design rule. Moreover, Al ions as an acceptor can be doped into the TiO2 films

for decreasing the leakage current.

The ever-shrinking dimensions of DRAM cells with the

increasing packing density have made the capacitor size increasingly smaller

and currently-used ZrO2 dielectric will not be able to maintain

necessary capacitance. Some high-k dielectrics like SrTiO3 have

been avoided for dielectric materials of DRAM capacitors because of their

complicated structures and compositions, however, it is time to face the

difficulties and overcome them. (STO k~300, ZrO2 k~50)

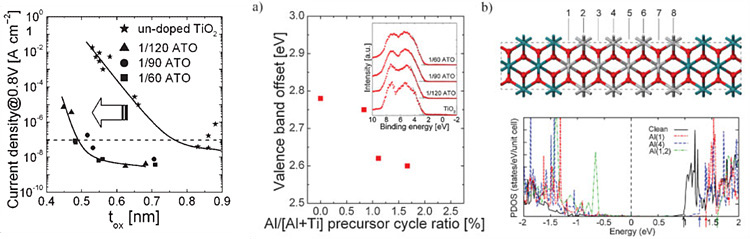

Deposition of Al-doped TiO2 dielectric film with ALD method

TiO2 film has high dielectric constant, which

varies with the phase of TiO2, 40 for anatase phase and ~100 for

rutile phase. However, rutile phase with high dielectric constant is thermally

stable at high temperature over 800℃, which is such high temperature for

conventional ALD process.

Our group has reported that ALD-grown TiO2 film

with O3 has rutile phase on Ru or RuO2 substrate because

of formation of lattice-matching RuO2 interlayer. The coherence of

crystallinity induces the in-situ crystallization of TiO2 into

rutile phase.

Related Paper:

S. K. Kim, et al., Adv. Mater, 20, 2008

Rutile TiO2 film has dielectric constant but

higher leakage current is attended due to its small band gap(3.1eV) and n-type

nature. To suppress the leakage current characteristic, Al2O3

layer is inserted between TiO2 layers. Controlling the concentration

of Al atom varies the electrical characteristics. Doped Al atom which acts as

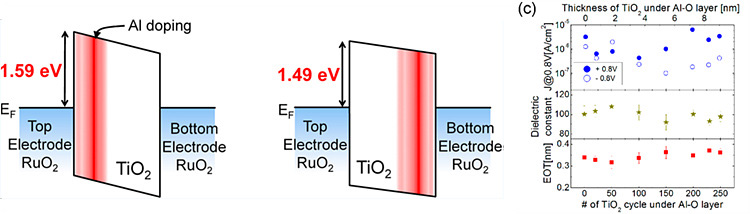

acceptor suppresses leakage current and lowers tox under 0.5nm.

Acceptor-like dopant Al atoms increases Schottky barrier

height(SBH) since the energy level of dopant site is under the oxygen vacancy

level of TiO2.

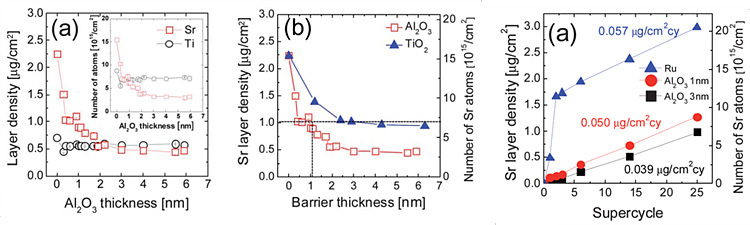

Position of Al2O3 layer in ATO film

also effects on electric characteristic of dielectric film. Lower leakage

current properties are shown when Al2O3 layer is inserted

near the electrode interface since leakage conduction mechanism of TiO2

film is Schottky emission conduction, which is sensitive to interface state.

Related Paper:

W. J. Jeon, et al., ACS Appl.Mater.Interfaces, 6(10),

2014

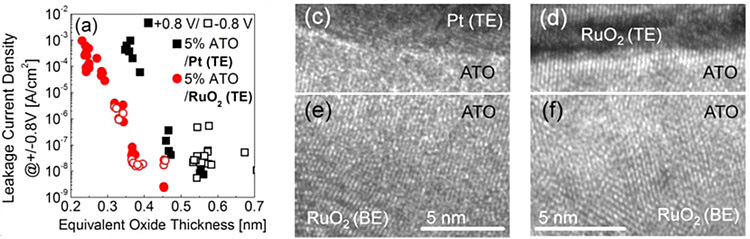

Further tox scaling of TiO2 under 0.4nm is achieved by adopting RuO2 top electrode in place of Pt top electrode. Just like the bottom electrode, RuO2 top electrode has structural coherence with TiO2 dielectric film and could reduce the tox of interface layer.

Related Paper:

W. J. Jeon, et al., ACS Appl.Mater.Interfaces, 6(23), 2014

Deposition of ALD-SrTiO3 dielectric film and controlling growth behavior

SrTiO3 (STO) dielectric film, which has higher

dielectric constant, about 300, is also being studied for dielectric material

for next generation DRAM capacitor. ALD method depositing STO film consists of

several SrO cycles and TiO2 cycles. Those layers are deposited

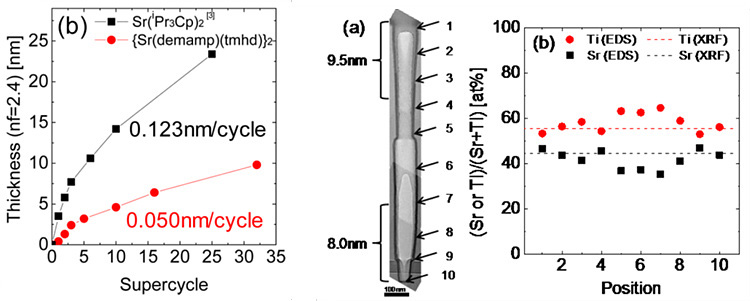

alternatively and the sub-cycle ratio is varied to gain STO film with

stoichiometric cation ratio.

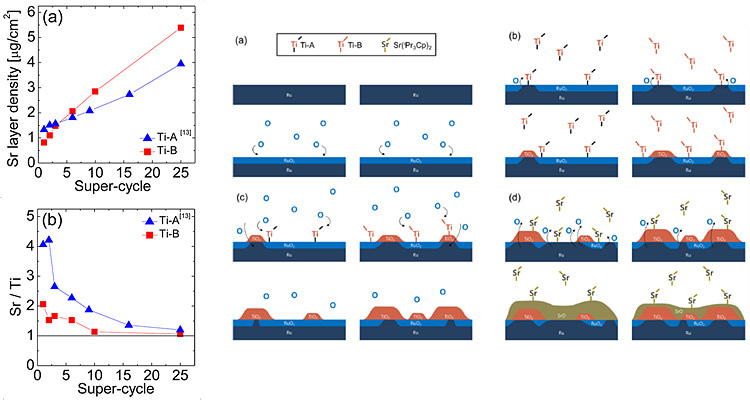

SrTiO3 film deposited on Ru substrate, which is a candidate of future DRAM electrode material, shows excessive growth of SrO layer since its oxygen-absorbing properties. The non-ideal excessive growth behavior could cause deviation of composition or thickness. Variation of the deposition process, such as temperature, precursor or inserting barrier layer has been studied for controlling growth behavior.

Related Paper:

W. Lee, et al., J. Mater. Chem, 22, 2012

Insertion of barrier layers like Al2O3 or TiO2 prevent the oxygen absorption of Sr precursor from oxidized Ru substrate. Barrier layers of certain thickness suppress the diffusion of oxygen atom and excessive growth is not shown. However, materials for barrier layer has lower dielectric constant than STO film so that net dielectric constant of capacitor decreases.

Related Paper:

W. Lee, et al., Chem. Mater, 25, 2013

Related Paper:

W. Lee, et al., Chem. Mater, 27, 2015

Variation of ALD precursor is another possibility for controlling growth behavior since the cause of non-ideal growth is the reaction between substrate-oxide layer or oxide-oxide layer. Using highly reactive precursor could enhance growth rate but excessive growth is also easily shown. Therefore, selecting proper precursor is important for ideal growth of STO film.

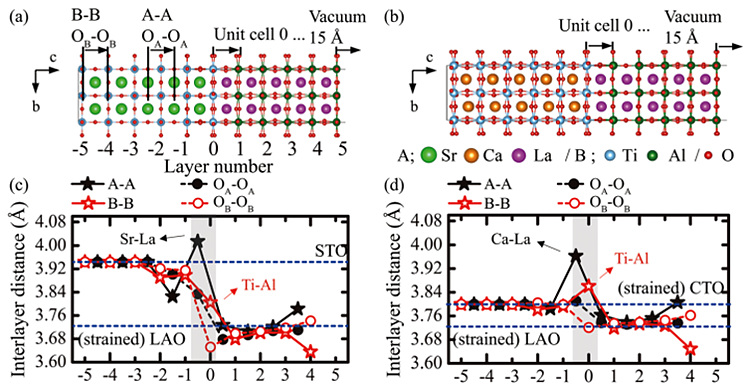

Ab initio modeling of perovskite hetero-interface (SrTiO3/LaAlO3&CaTiO3/LaAlO3)

The recent growth techniques enabling the fabrication of the

oxide hetero-structures with atomically abrupt interfaces between dissimilar

materials allow us to investigate the physics of emerging phenomena arising at

the interface. One of the striking examples is the recent discovery of

two-dimensional electron gas (2DEG) at oxide interfaces: electrically

conducting layer is formed at the insulating LaAlO3 (LAO) and SrTiO3

(STO) interfaces. We investigated the symmetry-dependent interfacial

reconstruction from ab-initio calculations as a way of relieving the

polar discontinuity at the interface which may coexist with the 2DEG. As model

systems, we used the hetero-interfaces of LAO/STO and LAO/CTO, where the

crystal structure of STO is cubic while that of CTO is orthorhombic. We found

that only B-B interlayer distance increased at the LAO/STO(fig. c), while both

A-A and B-B interlayer distances increased at the LAO/CTO which corresponds to

the unit cell expansion at the interfacial region(fig. d). Moreover, the

octahedral tilt was found to play a crucial role for the interfacial reconstruction

and occurred in different ways depending on the crystal symmetry of the

materials that consist of the interface. Our finding provides an insight not only to understand the

fundamental physics of the emerging properties at the oxide interfaces but also

to design unique functional interfaces.

Related Paper:

J. Lee, et al. Appl. Phys. Lett. 106, 071601 (2015)