HOME > Research > Resistive Switching RAM

HOME > Research > Resistive Switching RAM

Resistive Switching RAM

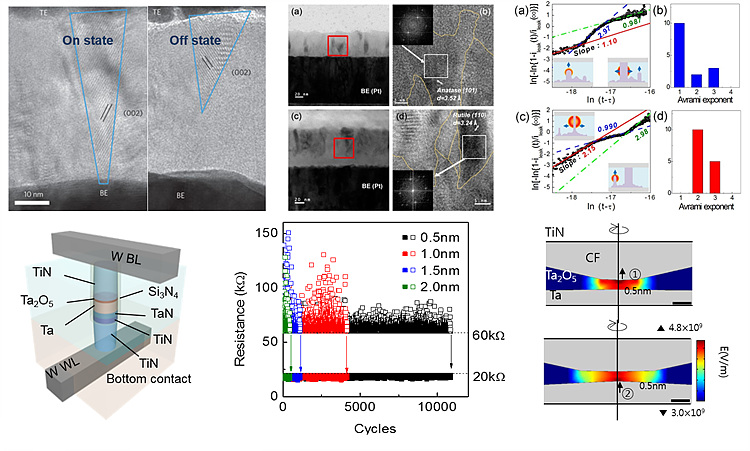

Resistive Switching mechanism study

Resistive switching (RS) memory is a strong

contender for highly scaled next generation non-volatile memory devices. It has

been well known that the RS behaviors mainly rely on the controllable soft

breakdown in normally insulating films through the electroforming process of

conducting nano-channels so-called filaments and their repetitive rupture and

rejuvenation process. It was verified that the Magnèli phase (TinO2n-1,

n≥4) transition plays a crucial role in the RS operation mechanism in TiO2

based RS memories through extensive high-resolution transmission electron

microscopy and electron diffraction analyses. It was the very first time that

conductive filaments were observed directly. Further electronic or ionic

bipolar resistive switching characteristic occurring at the filament ruptured

region was studied.

An

additional method that identify the real-time evolution of conducting

nano-filament by applying the Johnson-Mehl-Avrami type kinetic model is

conducted. In PEALD sample whose pristine state is anatase phase, the

rejuvenation of the filament is accomplished by repeated one-dimensional

nucleation followed by a two-dimensional growth. In sputtered film whose

pristine state is rutile phase, however, one-dimensional nucleation-free

mechanism dominates because of compatibility between rutile and Magnèli phase.

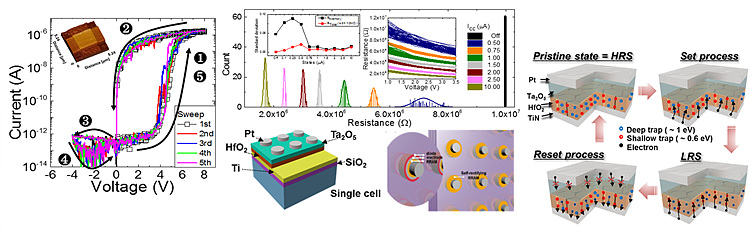

On

the other hand, Ta2O5 based RS memories show different

switching behavior because they have no stable and oxygen-deficient phase in

Ta-O systems. In this systems, filaments are formed by the drift of oxygen

vacancies under the application of electric field. It is hard to exquisitely

control the RS behavior in ultra-thin and small devices because the shape of

the conductive filament looks like an hour-glass. As such, the formation and

rupture of the filament should be conducted by the same polarity voltage.

Related Papers:

K. M. Kim, et al., Appl. Phys. Lett. 90 24,

242906 (2007)

K. M. Kim, et al., Appl. Phys. Lett. 91 1,

012907 (2007)

K. M. Kim, et al., Appl. Phys. Lett. 94 12,

122109 (2009)

D. H. Kwon, et al., Nature Nanotechnol. 5,

148-153 (2010)

S. J. Song, et al., Appl. Phys. Lett. 96 11,

112904 (2010)

K. M. Kim, et al., Nanotechnology 21 30,

305203 (2010)

K. M. Kim, et al., Nanotechnology 22 25,

254010 (2011)

K. J. Yoon et al., Nanotechnology, 18, 23,

185202 (2012)

S. J. Song, et al., Sci. rep. 3, 3443 (2013)

K. J. Yoon et al., Nanotechnology, 14, 24, 145201 (2013)

K. J. Yoon et al., Nanoscale, 6, 2161

(2013)

Improving the Resistive Switching Property

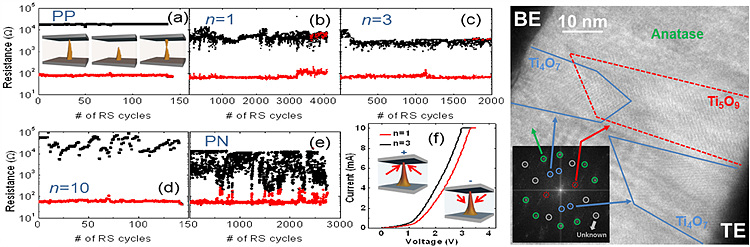

Improved electrical endurance can be

obtained in a crossbar type Pt/TiO2/Pt structure by using a modified

bias scheme. With a conventional bias scheme, for example positive set and

positive reset, conical shape conduction filament having a narrower cross

sectional area at the anode interface is formed in the TiO2 memory

layer. Because resistive switching occurs near the top electrode, it causes a

rapid oxygen consumption leading to the poor electrical endurance. To prevent

the rapid oxygen consumption, a modified bias scheme composed of a series

application of positive and negative bias is used. As a conical filament shape

is generated by a single bias scheme, the modified bias scheme results in an

hourglass shaped conduction filament as confirmed by the HRTEM of the device

after repeated switching cycles. Eventually, the oxygen consumption is

effectively suppressed and the switching endurance was highly improved.

Related Papers:

K.M. Kim et al., Electrochemical and

Solid-State Letters, 6, 13, G51-G53 (2010)

G. H. Kim, et al., Appl. Phys. Lett. 98, 262901 (2011)

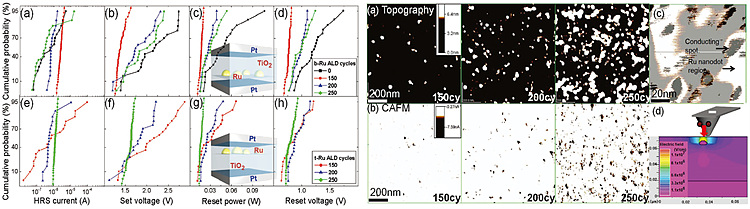

Switching uniformity is another critical issue

for resistive switching memory. The formation and rupture of conduction

filament are stochastic phenomena so they give highly scattered operation

parameters. The variability of the operation parameters was compared for the

cases where Ru nano-dots were embedded in the vicinity of bottom or top

interface region of a Pt/TiO2/Pt resistive switching cell. Combined

with ATLAS simulation results, the AFM and CAFM analysis reveal that the Ru

nano-dots role as either a local field enhancer or field suppressor when

inserted at the cathode or anode interface, respectively. Therefore, limiting

the location where electron injection occurs at the cathode interface to a

narrower region was the key factor for achieving highly improved RS uniformity.

Related Papers:

J. H. Yoon, et al., Appl. Phys. Lett. 97,

232904 (2010)

J. H. Yoon, et al., Adv. Mater. 25, 1987-1992 (2013)

Selector Employed 3D RRAM Crossbar Array Intergration

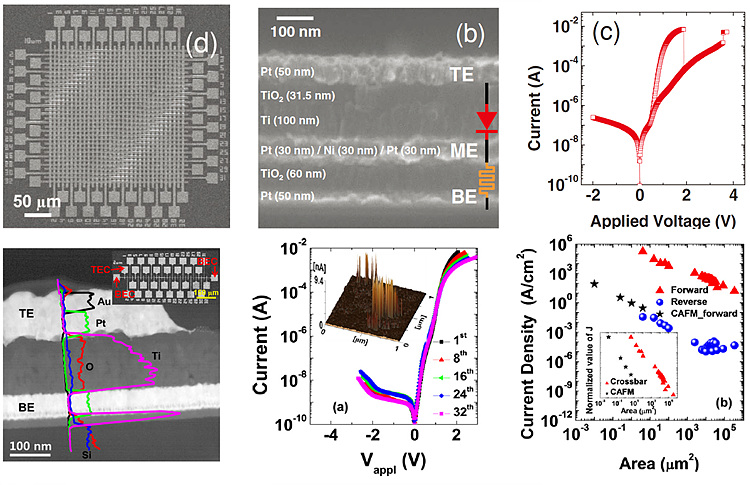

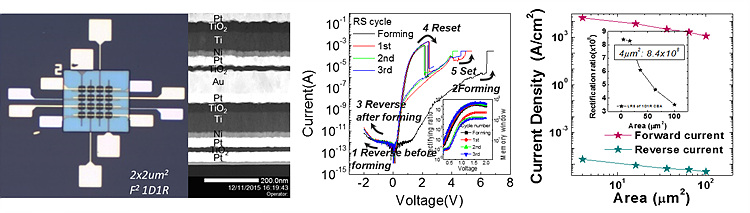

32x32 crossbar array(CBA) of >1kb RRAM

was fabricated. Each cell is comprised of 1diode-1resistive switching memory

stack, where a diode selector was employed for each resistive switching element

to alleviate the sneak currents issue in the CBA. In order to accomplish the

stack, a Pt/TiO2/Ti/Pt diode was stacked above a Pt/TiO2/Pt

unipolar resistive switching memory. The diode selector adopted the TiO2

deposited by ALD method with O3 as the oxidant. The maximum

rectification ratio achieved in the diode was >106, while it was

>105 in the 1D1R device. The high rectification ratio is

attributed to the high Schottky barrier at the Pt/TiO2 and the

quasi-Ohmic conduction through the TiO2-x/Pt, which is obtained by

the partial oxidation of Ti during the subsequent oxide deposition. Conduction

through a local conducting paths was confirmed for the both injections, based

on the electrode area dependent current density and the conducting AFM

measurements.

Related Papers:

G. H. Kim et al., Adv. Funct. Mater., 11,

23, 1440 (2012)

G. H. Kim et al., Appl. Phys. Lett. 21, 100, 213508 (2012)

Double-layers stacked RRAM was demonstrated in 4x4x2 CBA. In order to avoid the thermal disruption issue during the stacking process, which is particularly critical for the diode layer embedding high chemical potential within the layer, room temperature sputtering was adopted for the deposition of every oxide layer. The room temperature fabricated Pt/TiO2/Ti diode showed even improved property with the rectification ratio of >108, which was still maintained in the 1D1R device. The enhancement in the diode rectifying property is mainly ascribed to the suppression of the partial reduction of TiO2, which degrades the performance of Schottky barrier at the Pt/TiO2 interface. A 2-bit operation of the 1D1R further scaled the cell size down to F2.

Due to the low per lithographic margin of

the aforementioned stacked RRAM structure, vertical RRAM structure adopting

etching process as the key fabrication technique is preferred. Since the middle

electrode placed in between the selector and the memory can no longer be

adopted in this structure, however, a self-rectifying RRAM comprised of only

the two different oxide layers is developed. The Pt/Ta2O5/HfO2/Ti

device showed a resistive switching based on trapping/detrapping mechanism,

accompanied with high rectification ratio of ~106. Furthermore,

the highly promising 3-bit operation was demonstrated.

Related Papers:

J. H. Yoon et al.,

Adv. Funct. Mater., 32, 24, 5086 (2014)

J. H. Yoon et al., Adv. Mater., 25, 27, 3811 (2015)

Study on Crossbar Array Architecture

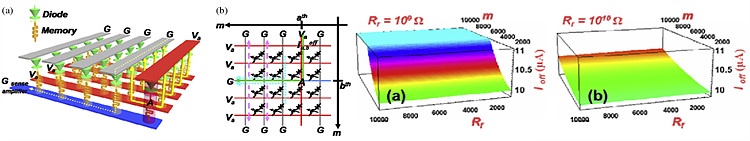

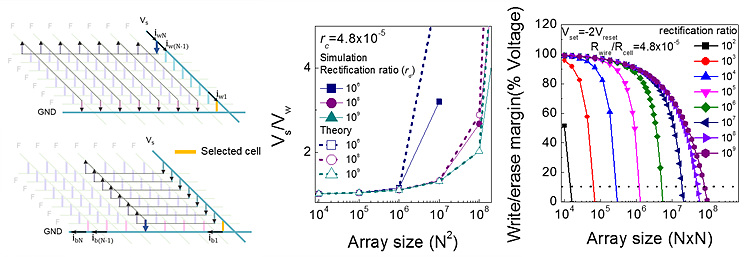

The diode requirements based on the sneak

currents analysis in a planar CBA has been examined. In CBA structure, the

sneak current paths comprise a parallel resistor component to a selected cell.

Therefore, unwanted sneak currents can interrupt the accurate reading of the selected

cell. By calculating all the possible sneak current components within a CBA,

the required rectification ratio and the forward current density of the diode

according to memory density has been evaluated.

Related Papers :

G. H. Kim et al., Nanotechnology, 21, 385202

(2010)

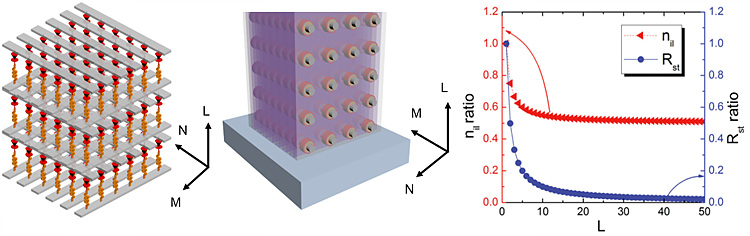

Further improved from the sneak currents

analysis in the planar CBA, sneak currents analysis on 3dimensional- (3D-) CBA

was examined. Two ideas of realizing the 3D RRAM structure was proposed:

cross-line structure, and word-plane structure. The cross-line CBA is the

structure where multiple layers of planar CBA are repetitively stacked, whereas

the word-plane structure is the structure where the selector and memory oxides

are overlaid on a vertically erected metal sidewall structure. Particularly for

the latter, the number of bit-lines sharing a word-line increases with the

increasing number of layers, therefore, sneak currents problem gets severer

with the increasing number of layers. Therefore, higher selector performance is

required for the word-plane structure compared to that of the cross-line

structure. However, the high per lithographic margin of the word-plane makes

the structure highly cost-effective, which is favorable for the ultimate

success of the 3D RRAM.

Related Papers :

J.Y. Seok et al., Adv. Funct. Mater., 34,

24, 5316-5339 (2014)

On the other hand, it has been recently found that the sneak currents can be problematic even during writing operation. The sneak currents may incur adverse voltage drop on the selected word- and bit- line and may also disturb the unselected cells on the sneak current paths. An analytical model for evaluating the increased writing voltage as well as the decreased writing margin due to the additional voltage drop on the selected word- and bit- line by the involvement of sneak currents has been deduced. A HSPICE simulation results provide the validity of the analytical model, while the model was applied to the 1D1R device eventually providing a plausible design strategy of the device in order for its implementation to a high density CBA RRAM.

Neuromorphic Engineering

Introduction to Neuromorphic Engineering

Neuromorphic engineering means the concept describing the use of very-large-scale integration (VLSI) systems containing electronic analogue circuits to mimic neuro-biological architectures present in the nervous system. The implementation of neuromorphic computing on the hardware level can be realized by oxide-based memristors, threshold switches and transistors.

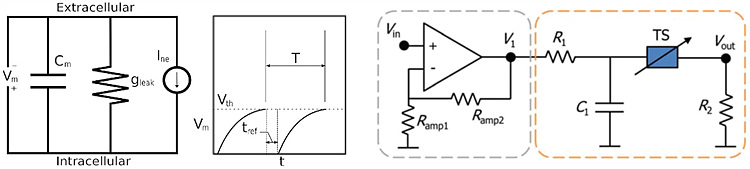

Relaxation oscillator-based leaky integrate-and-fire

Leaky integrate-and-fire (LIF) model is the

most popular model of a neuron. Leaky integrate-and-fire model consists of a

capacitor like cell wall in real neurons and a resistance to make a leakage

current. (Left figure) As input current is applied, voltage difference between

extracellular and intracellular is increased. When the voltage reaches to

threshold voltage, LIF neuron fires a spike and the voltage comes back to

resting voltage.

One way to construct hardware LIF neuron is using relaxation oscillator as LIF neuron, so called relaxation oscillator-based LIF neuron (ROLIF neuron). The right figure shows structure of ROLIF neuron which uses Pearson-Anson oscillator (PAO) as relaxation oscillator. As input current is applied, voltage on threshold increased because of the capacitor. When the voltage reaches to threshold voltage, threshold switch (TS) is changed to low-resistance state (LRS) and it causes increase of Vout which means spike firing. Since TS is changed to LRS, voltage on TS becomes lower and it makes TS changed to high-resistance state again.

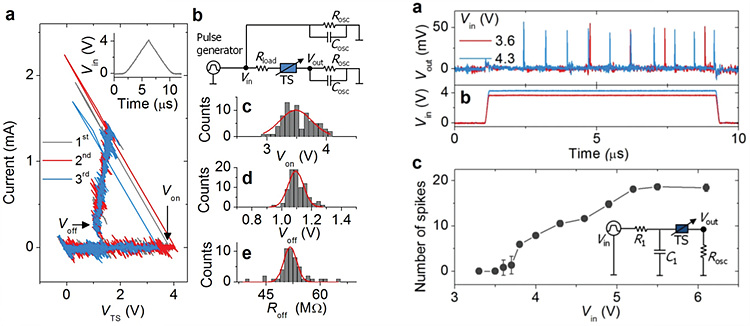

In ROLIF neuron, properties of threshold

switch are very important. For example, the left graphs shows the properties of

Pt/GeSe/Pt TS.

Top-right graph shows the spike train from

ROLIF neuron. The activity, the number of spikes in a given time period(8 μs), tends to increase with Vin.

To highlight this relationship, we further

identified the change in the number of spikes upon Vin (right-bottom

graph). First, the graph reveals that there exists a threshold voltage for

spiking (ca. 3.5 V) that is determined by Von. At Vin

below this threshold, VTS cannot reach Von, so no spike

is evoked. Second, the number of spikes tends to gradually increase with

increasing Vin in a wide Vin range. This change in the spike number

is attributed to a decline in the inter-spike interval (ISI) with Vin.

Third, the activity is saturated at a high Vin (>ca. 5.2 V). The

capacitor’s charging and discharging is in need of

non-vanishing time. Thus, this minimally required time delimits the minimum

ISI, i.e., maximum spike number.

Related Paper:

H. Lim et al., Nanoscale, 18, 9629-9640 (2016)